What do we produce?

SWAN Machine is focus on designing and providing the highest quality corner forming machine equipment,

SWAN develops with cutting-edge technology and considerate service. From custom designing&engineering to fabrication then to commissioning & training,

SWAN Corner Forming Machine offer corner forming(round corner forming) solution. It takes our metal corner forming services to new a new level.

What do our SWAN CORNER FORMING MACHINE used for?

SWAN corner forming machine are used for the corner forming of sheet metal industry, such as cold rolled sheet, aluminum sheet and stainless steel. Widely used in switch cabinet doors,electrical cabinets, electrical enclosures, switchgears, road signs, cover plates, aluminum veneer curtain walls, switchboards, container covers, household appliances, instrumentation, etc.

Our quality?

29 Years of Quality

Corner Forming Machine Body Frame:

The frame of our machine is blanked by plasma cutting machine, and used after weathering for 6 months. This can reduce tension and avoid deformation on the machine body.

Corner Forming Machine Main parts:

1. Main parts processed by CNC, The corner former rollers tools are made of high carbon chromium bearing steel, and the hardness achieve HRC 60-62 degree.

2. The parts are processed as blanking, heat treatment, lathing, grinding, electroplating, fine grinding.

3. 100% Test for each part, not sampling

4. The corner former rollers tools are with surface hardness up to HRC60-62 and concentricity accuracy up to ±0.005mm, ensure long service life and high straightening accuracy.

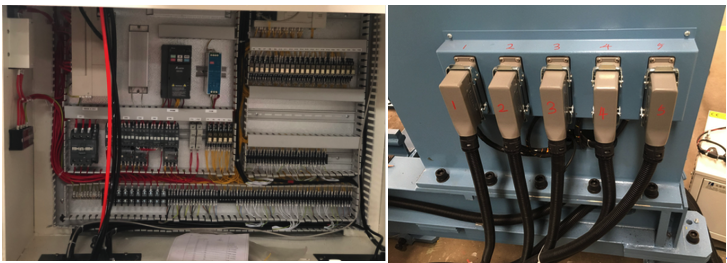

Corner Forming Machine Electrical system parts:

- Corner forming machine with CE standard.

- Famous brand components, such as Mitsubishi PLC, Schneider AC contactor, and Yaskawa servo driver and motor.

- The safety protection system is adopted to greatly reduce the failure rate of the machine.

- Can be changed to aviation plugs according to customer’s request.

Our certifications?

SWAN Corner Forming Machine are Certified with European CE. Other safe certifications is available but Involve more effort, please contact us when need.

In addition to Corner Former, SWAN can provide the production of corner former machine systems on the customer’s design.

What are the warranties for corner forming machine?

24 months for mechanical structures

12 months for electrical components

24×7 hours service

For any problem due to our quality within warranty, we will send new parts to customers for free (including express cost).

We will arrange engineer to do repair jobs in customer’s factory (for free) if customer cannot solve it by itself.

How much does corner forming machine cost?

50% to 70% of a similarly equipped ACF Brand Corner forming machine.