Corner Forming line with a hydraulic press and cutting

The present invention relates to a method of processing corners of metal panel, and more particularly to a method of processing corners of metal panel without tearing or notching of the material of the metal panel, So that a Sealant or a welding process is not needed.

A conventional method of processing corners of metal panel includes cutting or pressing the corners of the metal panel bending the corners, and then Sealing with Sealant or welding at the teared portions. As a result, Since the Surface of the metal panel is exposed, its appearance is not imperfect and at a step of joining the metal panels, many problems, Such as water leakage, noise, particles, absorbents, etc., occur when the Sealing process is performed. Further, if the welding process of the metal panels is performed, many problems Such as deformation, bending, and twisting of the panel occur because of the heat generated by welding. Moreover, when the corners of the metal panel are processed by a hydraulic press, Since various molds are necessary according to the Standards of products limited.

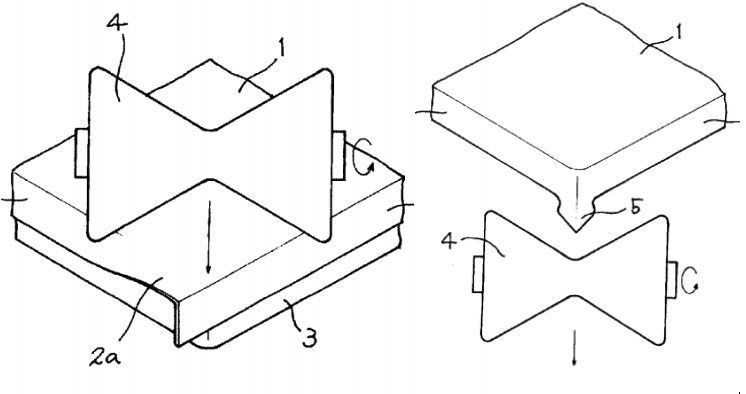

Therefore, it is an objective of the present invention to provide a method for processing the corners of metal panels without tearing or notching of the material of the metal panel, So that a Sealing or welding process thereof is not needed. Accordingly, it is possible to improve the quality of the products including Such metal panels as used for interior and exterior decoration in buildings, by essentially eliminating the factors causing imperfections in the products. It is also possible to Simultaneously process one or more corners of the metal panel irrespective of the Standard of the metal panels. As a result, it is possible to obtain the good quality metal panels of various Standards and improve the productivity manufacture of the metal panels. The present method according to a invention comprises the Steps of bending the metal panel as desired, the bent end portion of a respective Side edge being bent not closer 100 mm from the edge thereof, and being then closely attached and fixed onto a Supporter, pressing the metal panel using a roller rotation, upwardly and moving in the Vertical direction to process the corners of the metal panel; and cutting unnecessary metal piece formed in the pressing Step.