SWAN Corner Forming Machine For Cabinet door panel

Fast corner former with CE Standard, 9sec forming one corner

SWAN Corner Forming Machine For Cabinet door panel forming prefect corners, No longer needed welding, NO set up. NO welding. NO grinding. NO finishing. NO polishing

SWAN Corner Forming Machine offer corner forming(round corner forming) solution. It takes our metal corner forming services to new a new level.

Flexible corner forming gives new opportunities in sheet metal production of panels or doors. Cold forming of corners on doors or panels in any material formable (Mild Steel, Stainless Steel, Aluminum, alloys and others) allow us to use any material thickness and individual flange heights.

Cold forming corner on door or Cabinet panel,

Benefits of Metal Corner Forming:

- 1.create high-quality corners

- 2.Suitable for different material(Mild Steel, Stainless Steel, Aluminum, alloys and others)

- 3.Time Saving (9Sec forming one corner)

- 4.Improved working conditions

- 5.Only 1 operator required

- 6.Very low noise, no dirt creation

- 7.CE standard

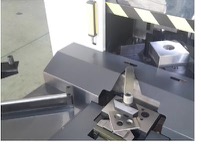

Corner Forming Process:

Step 1: At beginning, cut metal sheet by shear or laser into required shape.

Step 2: Hydraulic Press Brake to bend panel flange edge (leave corner unbend).

Step 3: Put target panel corner on corner forming machine square die station to forming the corner.

Step 4: Put formed corner on cutter station to cut the scrap edge.

Corner Finish.

Final Corner lay-out product sample: