FLEXIBLE CNC Automatic Corner Forming Machine

NO welding, NO grinding, No hand finishing work

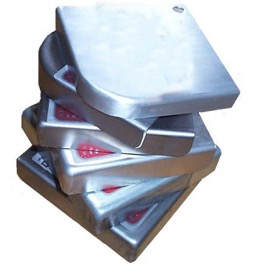

PRODUCT PROFILES

Features

The flexible corner former for panel and door fabrication allows you to create high quality corners up to 10x faster than welding, which reduces cost.

A new flexible state of the art technology known as: FLEXIBLE Corner Forming Machine

gives new opportunities in metal sheet production of panels or doors. Cold forming of corners on doors or panels in any material formable (Mild Steel, Stainless Steel, Aluminium, alloys and others) allow to use any material thickness and individual flange heights

Corner Forming Machine COST & TIME SAVINGS:

Cost Saving:no welding, no hand finishing work; only 1 operator required; elimination of abrasives and welding consumables;

SPECIFICATION:

|

technical parameters |

Content |

|||

|

Model |

LMS-1-1 |

|||

|

Processing Range (mm) |

Material |

Thickness |

Flange height (Max.30mm) |

Corner radius |

|

Cold-rolled plate |

0.5-1.2 |

Less than 25 times of the thickness of the plate |

1.5-50 |

|

|

1.2-3.0 |

Less than 20 times of the thickness of the plate |

1.5-50 |

||

|

Aluminum plate |

0.8-1.2 |

Less than 25 times of the thickness of the plate |

1.5-50 |

|

|

1.2-3.0 |

Less than 20 times of the thickness of the plate |

1.5-50 |

||

|

Stainless steel plate |

0.5-1.2 |

Less than 20 times of the thickness of the plate |

1.5-50 |

|

|

1.2-2.5 |

Less than 15 times of the thickness of the plate |

1.5-50 |

||

|

Dimensions of workpiece |

140×140, Max. no limited |

|||

|

Processing time moulding one corner |

About 9 sec. |

|||

|

Processing time moulding fours corners |

About 60 sec. |

|||

|

Mould configuration |

Rolling mould ,square mould ,shear knife |

|||

|

AC servo motor |

Fuji/Japan |

|||

|

Pneumatic System |

Airtac/Taiwan |

|||

|

PLC |

Mitsubishi/Japan |

|||

|

Low voltage electrical appliance |

Schneider /France |

|||

|

hydraulic valve |

Huade/China |

|||

|

Main motor power(KW) |

4 |

|||

|

Dimensions(Length×Width×height) (mm) |

1560*1330*1600 |

|||

|

Weight(KGS) |

1260 |

|||