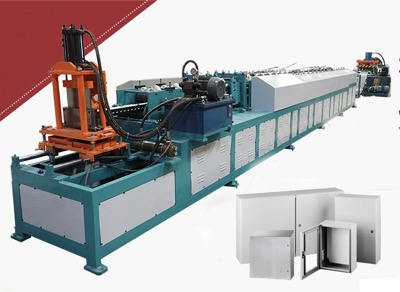

SWAN Electrical Enclosures Cabinet Panel Roll Forming Machine

CE Standard, Mitsubishi PLC, Fast metal sheet corner former High -speed, dependable, and flexible

How to manufacture mild steel wall mount Electrical Enclosures box frame? SWAN Electrical Enclosures Cabinet Panel Roll Forming Machine provide prefect solution to manufacture metal enclosures panel for electrical box making industry.

Step1: Use Roll forming machine to manufacture Enclosures Panel (Cut-to-Length), with finished notching and fixed length.

Step 2: Bending Enclosures

manually bend the panel into enclosures.

Step 3: Finished Electrical Box

welding with back / door panel and finish.

Enclosures panel roll forming machine Production Flow:

Material Coil – Decoiling – Leveling – Servo-Feeding – Pre-Punching – Roll Forming – Post-Punching – Hydraulic Cutting-Off -Finished Panel.

including: 1, Decoiler; 2, Leveling Device; 3, Servo Feeder; 4, Pre-Punching Unit; 5, Roll Forming Machine; 6, Straightening Device; 7, Post-Punching Unit; 8, Hydraulic Cut-off Device; 9, Run-Out Table; 10, Cooling System; 11, Hydraulic System; 12, Electrical Control System.

Decoiler

Operation: motorized

Mandrel expansion: manual

Uncoiling speed: 16m/min

Suitable for most kind of coil material, such as CR steel, GI Steel, stainless steel, aluminum etc.

Straightener/ leveler: