SWAN CNC Corner Forming Machine

Europe CE Standard&Automatic fast corner forming(5 seconds)&No weldingSWAN Machine are focus on manufacture corner forming machine for metal sheet road signs and electrical cabinets(enclosures / switchgears) sheet metal plate corner forming. CNC corner forming machine is a metal sheet corner former which provides the best solution for cold rounded corners in traffic signs, cover, doors, panels and other flat sheet metal parts.Famous brand Electronic components, Such as Mitsubishi PLC, Schneider etc.

WHY CHOOSE SWAN CORNER FORMING MACHINE ?

SWAN is a manufacturer of Corner Forming Machine serving both the commercial and metal sheet industries for the past 17 years. Today SWAN’s cornerformers are used by 280 companies in the world, specifically in the areas of electrical enclosures,door, panel, road signs industries. Swan corner forming machine always guarantees top performances in corner forming production and cost-cutting, thanks to its state-of-the-art technology. A large part of SWAN’s corporate strategic plan is the adoption of our Core Values: Safety, Accountability, Customer-Focused, Respectful, and Teamwork…. Learn more >>>

Best Corner Forming Machine

- European CE standard

- NO welding. NO grinding. NO polishing

- Time Saving (9Sec forming one corner)

- Suitable for different material(Mild Steel, Stainless Steel, Aluminum, alloys and others)

- Create high-quality corners

Corner Forming Machine Design

- SWAN Corner Forming machine experienced in-house engineers are standing by to build customized proposal to realize customer target in terms of productivity, flexibility and investment pay back.

Corner Forming Machine Manufacturer

- Roller Tool HRC 60-62 degree hardness for forming prefect corner

- Main parts are processed as blanking, heat treatment, lathing, grinding, electroplating, fine grinding

- 24×7 hours service

- OEM

SWAN CORNER FORMING MACHINE

Metal Sheet Panel Corner Forming Solution

Automatic CNC Corner Forming Machine

Automatic corner forming machine is a multipurpose corner former that cold forming seamless corners without welding and grinding. Fast corner rounding formable material with thicknesses from 0.5 to 5 mm, corner angles of 60 to 150 degrees, and corner radius of 2 to 50 mm.

The corner former has substantially reduced labor costs associated with electric enclosures, The same operator does the bending and the corner forming in about one minute per part. Now we can shift employees to ease welding and grinding bottlenecks in other.

In addition, corner forming eliminates the need for stacking to weld and restacking to grind. The part does not need to be transported to the welding department and then again to the grinding department. Operators move the part once to the corner former. areas of the company View more>>

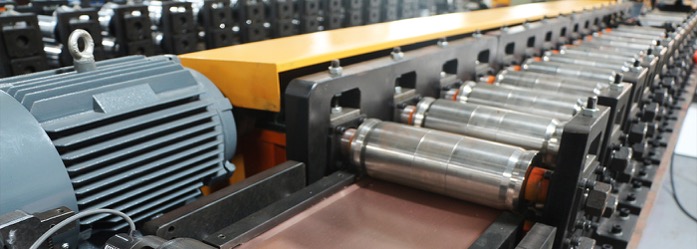

Electrical Enclosures Cabinet Panel Roll Forming Machine

Electrical enclosures cabinet panel roll forming machine production line. It is manufacture electrical enclosures frame, enclosures panel.door panel for switchgears cabinet. It is adopt cold roll forming process technology forming metal frame or panel.punch hole and PLC control automatic. View more>>

Electrical Enclosures Door Panel Roll Forming Machine

Electrical Enclosures Door Panel Roll Forming Machine suitable for GI/CR Steel coil material, thickness 1.1mm, including Decoiler, Leveling Device, Servo Feeder, Pre-Punching Unit, Roll Forming Machine, Straightening Device, Post-Punching Unit, Hydraulic Cut-off Device, Run-Out Table, Cooling System, Hydraulic System, Electrical Control System. View more>>

APPLICATIONS OF CORNER FORMING MACHINE

Corner Forming Machine for enclosures panel

In response to Mild steel wall-Mount enclosures panel. Swan company has developed corner forming machine that specializes in the corners of the enclosures panel. door panels. With the swan corner forming machine angle forming machine, only the four sides of the plate are pre-bend, and the corners form a bell mouth shape, which can then be processed on the corner forming machine. Moreover, the size of the door panel can be arbitrarily changed. With a set of molds, door panels of different thicknesses and sizes can be machined. And the four corners of the door panel and the surface of the door panel are an organic whole, which does not require welding, grinding, etc. The corners are very beautiful, and the uniformity is high, which can make the subsequent plating and spraying adhesion strong and durable, and also greatly improve the production. Efficiency and improved working……..[learn more]

Corner Forming Machine for traffic sign

In response to Mild steel wall-Mount enclosures panel. Swan company has developed corner forming machine that specializes in the corners of the enclosures panel. door panels. With the swan corner forming machine angle forming machine, only the four sides of the plate are pre-bend, and the corners form a bell mouth shape, which can then be processed on the corner forming machine. Moreover, the size of the door panel can be arbitrarily changed. With a set of molds, door panels of different thicknesses and sizes can be machined. And the four corners of the door panel and the surface of the door panel are an organic whole, which does not require welding, grinding, etc. The corners are very beautiful, and the uniformity is high, which can make the subsequent plating and spraying adhesion strong and durable, and also greatly improve the production. Efficiency and improved working……..[learn more]